Grain Gadgets

Monitoring Tech to Keep Tabs on Your Bins

You’ve already put a lot of time and investment into your grain over each harvest season, so you want to make sure it has the right environment and conditions. Excess moisture, higher temperatures or lack of air flow can have disastrous effects on your yield, and in a moment, you can be left with nothing.

Grain monitoring technology and equipment can make your storage more efficient and profitable while giving you the peace of mind that your inventory is protected.

GrainVue

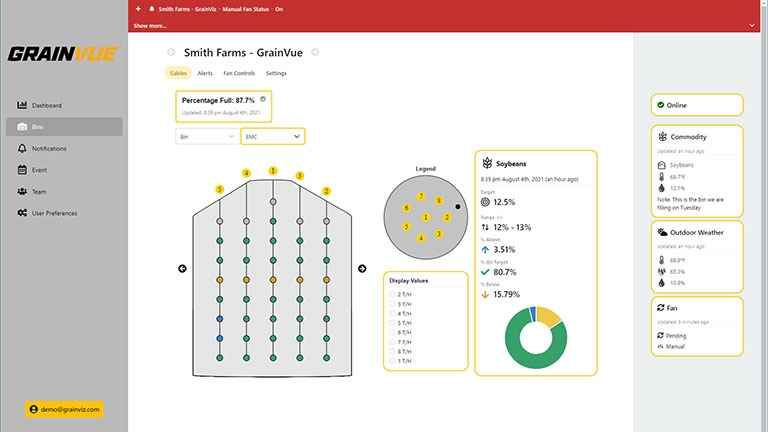

The GrainVue system by GSI offers a comprehensive solution for managing stored grain through automated aeration and real-time monitoring. Designed specifically for on-farm storage, the platform uses digital cable technology to track moisture, temperature and inventory levels across each bin.

With the addition of a connected weather station and fan module, producers can automate fan operation to cool, dry, maintain or rehydrate grain as needed. GrainVue also supports early spoilage detection by alerting users when carbon dioxide levels rise — a common indicator of grain degradation. The smart aeration modes allow fans and heaters to respond to site-specific conditions, reducing energy use while protecting quality.

The user-friendly interface allows management decisions from virtually anywhere through remote access. With customizable alerts and cloud-based connectivity, GrainVue is built to minimize risk while extending safe storage timelines, especially during warmer months when temperature fluctuations can accelerate spoilage. One gateway per bin site transmits the data securely to the cloud.

GrainTrac

Offering real-time access to temperature data and fan control from a smartphone or computer, GrainTrac is a remote grain monitoring system designed for on-farm use. The system records readings four times per day and sends the information to a secure website to help producers monitor conditions across one bin or an entire site.

Users can configure alarms, receive text or email alerts and control fans remotely to optimize grain preservation and energy use. GrainTrac is compatible with existing monitoring systems and can be easily expanded as farm needs grow. An optional WeatherTrac station allows for integration of localized weather data, further enhancing aeration decisions.

Additional features include theft detection alerts and a low annual service fee. The system is built to provide timely updates and long-term grain quality protection without requiring frequent manual checks, making it a practical tool for managing stored grain efficiently.

Tri States Grain Conditioning | www.tsgcinc.com

TMS6000

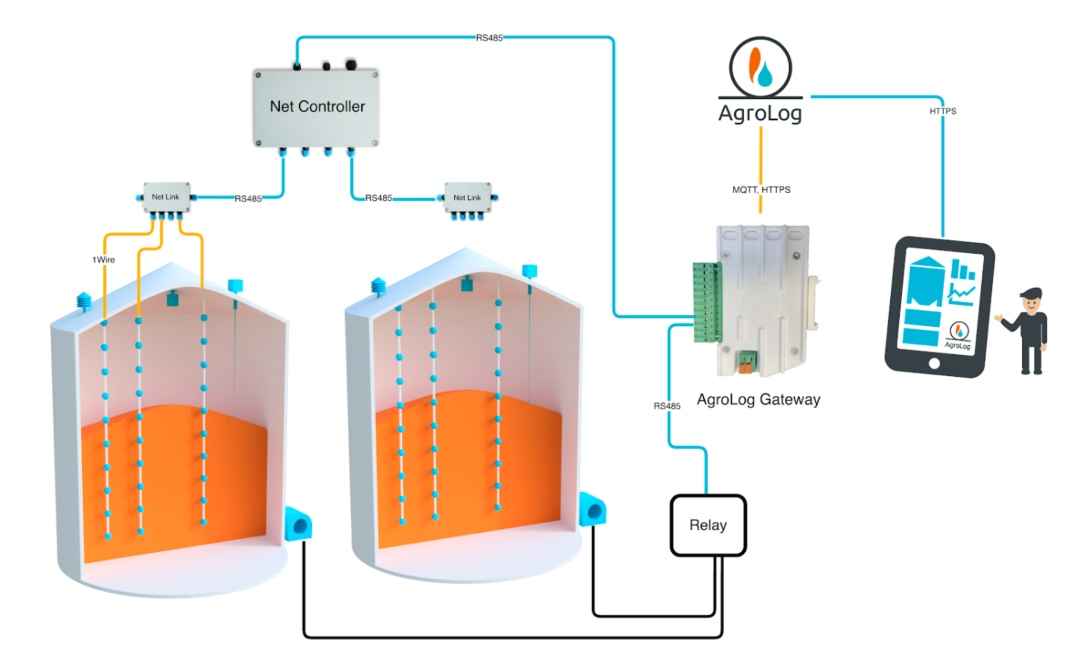

The TMS6000 is an advanced grain bin monitoring and control system designed to protect stored grain through real-time data collection and automated management. The system integrates hardware sensors with intelligent software to monitor temperature, moisture, carbon dioxide levels and inventory across multiple silos or bulk storage sites.

Users can customize the number and type of sensors, choosing between cloud-based or on-premise solutions tailored to their operation’s size and needs. The TMS6000 software provides around-the-clock monitoring via smartphone, tablet or personal computer, with alerts for critical changes to help prevent spoilage and ensure safety.

Aeration fan control is automated based on grain and ambient conditions, optimizing moisture and temperature management. Headspace monitoring to reduce condensation and level measurement to track inventory are additional available features. The system supports integration with third-party platforms through REST API and offers centralized management of multiple locations. Its modular design aims to provide flexibility, ease of use and comprehensive protection for grain storage operations.

Perten AM 5200-A

The Perten AM 5200-A is a commercial-grade grain moisture tester trusted by grain inspectors, terminals, elevators and farmers for fast, lab-accurate results. Approved by the U.S. Department of Agriculture, the Grain Inspection, Packers and Stockyards Administration/Federal Grain Inspection Service, and the National Type Evaluation Program for legal trade, it measures moisture, test weight and temperature in grains, oilseeds, pulses, lentils and more.

Using Unified Grain Moisture Algorithm-compatible radio frequency dielectric technology at 150 megahertz, it delivers results in 10 seconds. Its cast-aluminum measurement cell and built-in electronics support long-term accuracy and repeatability. A large copper temperature sensor ensures accurate readings on hot samples from the dryer and frozen samples in winter.

The AM 5200-A features auto loading, unloading and analysis, along with a self-cleaning lower door that prevents dust buildup. The large color touchscreen is easy to use, even with gloves, and data can be exported via USB, Ethernet or serial. Built for durability, accuracy and repeatability, the unit performs reliably in high-volume commercial settings and on the farm.

Scott Ag Solutions | www.scottagsolutions.com

Bin-Sense Plus

For producers looking to improve storage efficiency and maintain grain quality without frequent manual checks, Bin-Sense Plus offers automated conditioning and hourly data updates. Bin-Sense Plus is a remote grain monitoring system designed to help optimize grain quality.

The system tracks temperature and moisture levels inside grain bins and can automatically operate aeration fans based on ambient air conditions. It is compatible with most existing sensor cables and requires AC power to function. Users can access real-time readings via mobile or desktop devices, with support for both iOS and Android platforms and customizable alerts delivered by text or email.

The system also includes a grain level indicator, which tracks inventory by yard, bin and grain type. Bin-Sense Plus can reduce the risk of spoilage and over-drying with automated aeration based on conditions both inside and outside the bin.