Cover Story: Thunder Creek Equipment - Maintaining the Purity of DEF

An Open Letter from Loren Van Wyk, an owner of Thunder Creek Equipment

An Open Letter from Loren Van Wyk, an owner of Thunder Creek Equipment

Our company has deep roots in production agriculture.

For decades, my wife Jean and I farmed a few thousand acres in central Iowa alongside our metal fabrication business, LDJ Manufacturing. One of constant challenges on the farm was getting fuel out to the equipment safely and then getting the equipment fueled quickly. We were using a 1000-gallon fuel barrel mounted on running gear. It was functional, but could only be pulled at slow speeds and was dangerous.

There had to be a better way.

Already an experienced trailer manufacturer and a nationally certified ASME tank manufacturer, we began work on a new low profile, square fuel trailer. They key features we were looking for were speed and safety to the field and rapid fueling to keep the farm machinery moving.

The first trailer was built in 2009 and branded with the name Thunder Creek Equipment. (The name comes from a creek that runs along the north side of the property where LDJ Manufacturing is located.) In the years that have followed, we’ve expanded the Thunder Creek line to bring new, innovate solutions to help you get more done in the field.

In 2011, for example, we developed a proprietary solution for handling diesel exhaust fluid. Since DEF was well on its way to becoming a part of daily maintenance of off-road machinery, it made sense that we would need a solution to bring it to the field as well.

In this article, we’ll share some of the expertise we have learned about handling DEF and what you need to know to protect your equipment and keep that machinery on the move.

The Background on DEF

In the 1990s, the Environmental Protection Agency identified diesel engine exhaust as a leading cause of pollution. They launched a series of regulations to be implemented in five phases – or tiers – between 1996 and 2014.

In the 1990s, the Environmental Protection Agency identified diesel engine exhaust as a leading cause of pollution. They launched a series of regulations to be implemented in five phases – or tiers – between 1996 and 2014.

The final stage, referred to as Tier 4 Final, took effect the beginning of this year. It applies to diesel engines in the 174-750 horsepower range and focuses on two specific pollutants from all diesel engines (both on- and off-road).

Particulate Matter – This is the “smoke” we used to see as exhaust. It’s mainly composed of small carbon particles and other toxic substances that were created when fuel was not completely burned.

Nitrogen Oxides – These gasses form during the combustion process. Some of which have been identified as a cause of acid rain.

Overall, the EPA’s efforts have been successful. The EPA’s tiered emissions program has reduced emissions of particulate matter and nitrogen oxides by 100 times from Tier 1 (1996) through Tier 4 Final (2014). This means that it would take a hundred of today’s diesel engines to produce the same level of pollutants that was created by a single diesel engine prior to the start of the EPA’s program.

2014 introduces the final tier of emission regulations for diesel engine exhaust. The solutions from all manufacturers of high horsepower diesel engines (175-750hp) now include the use of a technology called Selective Catalytic Reduction (SCR).

SCR technology involves a process where diesel exhaust fluid (DEF) is injected into the engine exhaust. This produces a chemical reaction inside a catalyst, converting nitrogen oxides to water and nitrogen before releasing them through the equipment’s tailpipe.

SCR is well established for on-highway applications, but its use is relatively new in off-road industries. This environment poses a unique challenge for operators, most notably the need for a clean and convenient way to get DEF to machinery in the field.

What Is DEF?

DEF is 32.5% synthetic urea and 67.5% de-ionized water. It’s not dangerous. It’s non-toxic, non-hazardous, and non-flammable.

DEF is 32.5% synthetic urea and 67.5% de-ionized water. It’s not dangerous. It’s non-toxic, non-hazardous, and non-flammable.

If a small amount is spilled it can be rinsed with water or wiped up. It is corrosive to some metals and plastics so it should be handled in the same way that a medical professional would handle sterilized equipment.

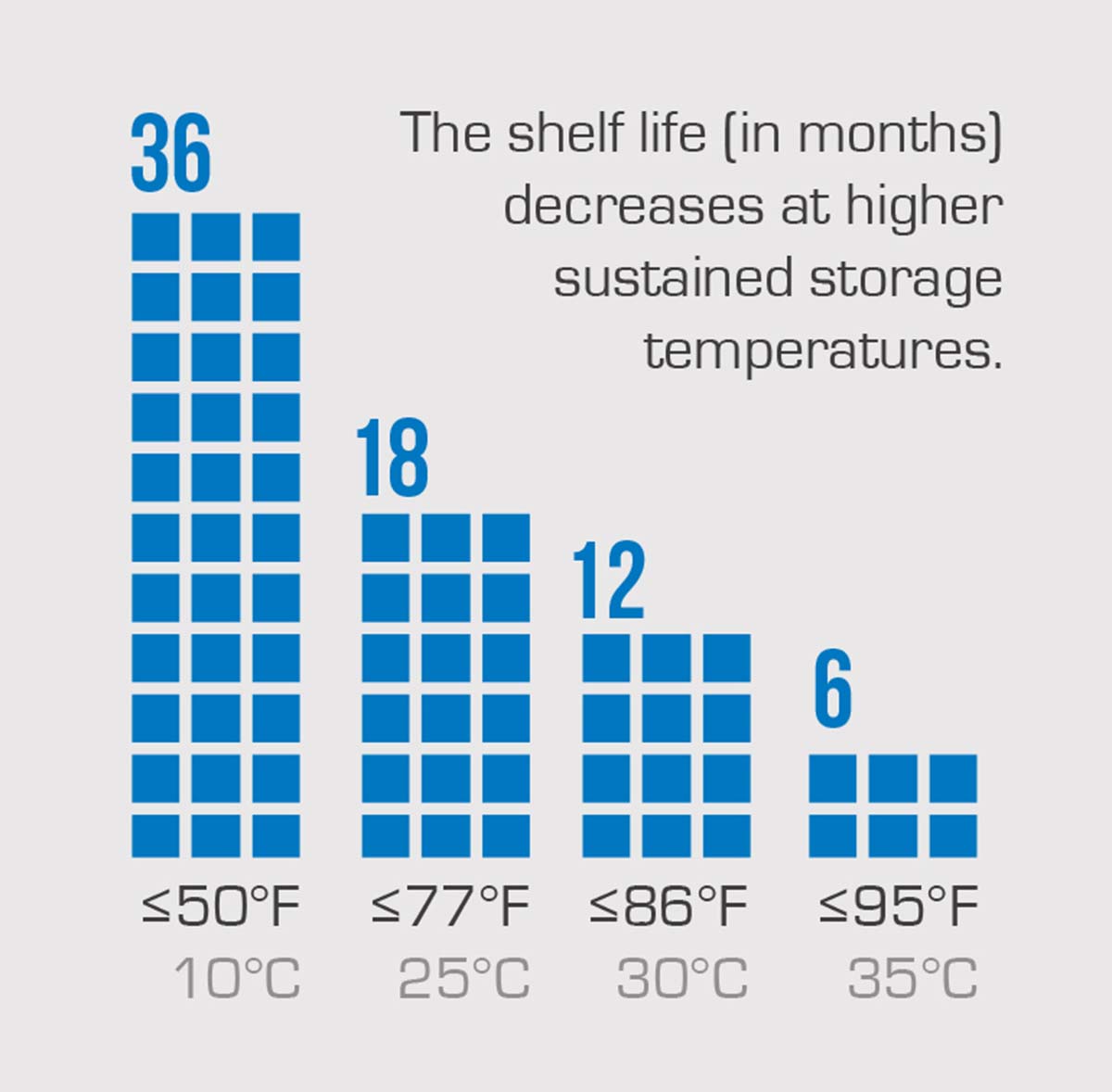

Temperature affects DEF, especially as it relates to shelf life. The chart on the [LOCATION] shows the how long the fluid is good depending on the temperature of the room where it is stored.

For colder climates, precautions must be taken to keep DEF from freezing. Though freezing doesn’t harm DEF, it can cause a fully filled, closed container to burst. Heating systems should be incorporated when the fluid will be exposed to prolonged temperatures below 12° F / -10° C.

Contaminated DEF

Contaminated DEF

The most important thing you need to know about DEF is that it is more susceptible to contamination than other fluids commonly used around the farm.

DEF can be compromised when it comes into contact with both direct and airborne contaminates. As little as a fraction of teaspoon of some elements - copper, zinc, iron, and aluminum to name a few – is enough to bring 5,000 gallons of DEF off-spec.

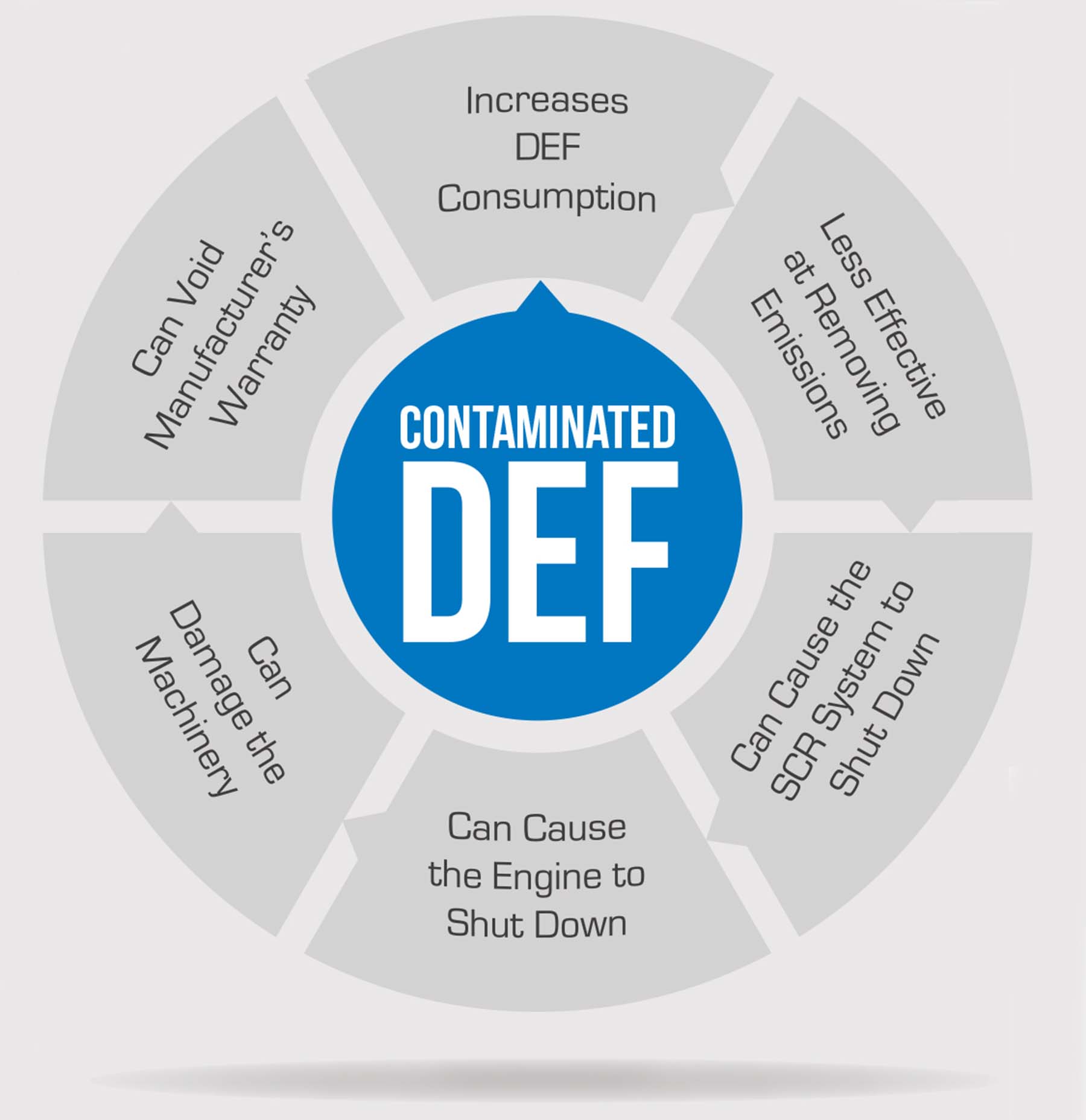

Contaminated DEF poses some risk to your operation. A system using contaminated DEF will consume more of the fluid and be less effective at reducing emissions from the exhaust.

Over time, this can damage the catalyst in the SCR system, causing the engine to shut down and leaving your team idle in the field. It may damage your machinery too, and a manufacturer could opt to void the warranty if damage is tied back to contaminated DEF.

Because DEF is so easily contaminated and purity is so crucial in the SCR process, the International Organization for Standardization has developed the ISO 22241 Standard for how DEF is manufacture red and how it should be handled and stored.

Here’s what you need to know to maintain the purity of DEF in your operation:

Here’s what you need to know to maintain the purity of DEF in your operation:

- Make sure your fluid is made in accordance with the ISO Standard by looking the API Diesel Exhaust Fluid Certification Mark.

- Use a container made for DEF. It should be constructed with materials approved in the ISO Standard, and rinsed and sealed properly.

- Maintain a clean, closed fluid path. The standard does allow for open systems, but they must be cleaned between each use. This isn’t practical in off-road environments, so closed loop systems are best here.

- Keep your workspace clean. Dirt and debris near the DEF fill port can also lead to contamination.

Thunder Creek Equipment’s DEF Delivery Solutions

“It’s imperative that DEF is stored and transported in a container that was designed and manufactured in accordance to the ISO 22241 standard,” says Loren Van Wyk, a developer of Thunder Creek Equipment’s DEF Delivery Solutions. “If you use a tank and pumping system that is not built to the standard, you introduce contaminates that can damage a SCR system which in turn shuts down the engine it’s mounted on.”

Thunder Creek offers three types of DEF Delivery Solutions in various sizes depending on your particular operation’s needs. All are designed and manufactured with strict adherence to the ISO 22241 standard and equipped with their patent-pending 2-in-1 DEF Pumping.

This proprietary solution allows users to fill from the bulk DEF supply, transport the fluid to the field, and dispense it into machinery. All of this is accomplished in a closed-loop to ensure there is no atmospheric exchange that could potentially contaminate the fluid.

What’s more, it uses just one pump, eliminating the need to purchase a separate DEF transfer pump, which can run upwards of $2000.

DEF Delivery Options for Fuel and Service Trailers

Thunder Creek Equipment is a leading manufacturer of fuel and service trailers, so naturally, adding DEF onto these platforms is the most popular option. They are  available in 40-, 60-, 100- and 330-gallon capacities so you can bring DEF to the field along with diesel fuel, parts, and tools. Heater options are available.

available in 40-, 60-, 100- and 330-gallon capacities so you can bring DEF to the field along with diesel fuel, parts, and tools. Heater options are available.

Bulk DEF Trailers

For operations requiring greater volumes, Thunder Creek has developed trailers for the sole purpose of transporting DEF. They are available in 500- and 990-gallon capacities. These are available with a self-contained, thermostatically controlled LP heating system for the tank and toolbox to protect the fluid in even the most remote environments.

DEF Transport Tote

New this year from Thunder Creek is the DEF Transport Tote. It brings the best of Thunder Creek’s DEF Delivery Solutions to the back of a standard truck bed. The tote houses a 50 gallon DEF tank and Thunder Creek’s patent-pending 2-in-1 DEF pumping system under a lockable, weather sealed door and can also be equipped with a heating system. It’s perfect for operations just starting to run their first pieces of machinery with SCR technology.

To learn more about Thunder Creek’s DEF Delivery Solutions or other information about properly handling DEF, visit ThunderCreekEquipment.com or call 866-535-7667.

Thunder Creek Equipment offers convenient, compliant, and contaminant-free DEF delivery solutions for many off-road applications and jobsites. Unlike other fuels and fluids, DEF is sensitive to chemical impurities and is easily contaminated. Thunder Creek’s closed loop system ensures the purity of the DEF is maintained to safeguard your equipment.