Smarter Spraying Starts with Better Adjuvants, Boost Efficiency and Cut Waste This Season

(Sponsored Content) — Across farms in the Midwest and beyond, efficiency has become the new measure of success. With input prices rising and weather windows shrinking, farmers have to make every spray pass count. A single afternoon of high winds or uneven coverage can undo days of hard work, wasting product and lowering overall effectiveness.

That challenge is getting tougher every season. Herbicides and fungicides are more advanced but also more expensive, and environmental regulations are tightening around drift and runoff. Even the best sprayer operators are battling against evaporation, inconsistent droplet size and changing field conditions.

This is where adjuvants come in, not as a luxury, but as a necessity. When properly matched to the tank mix, adjuvants help sprays stick better, spread evenly and stay where they’re supposed to. It’s one of the simplest, most cost-effective ways to protect every dollar invested in crop protection.

At WC Processors, the focus is on practicality. Their lineup of adjuvants is built for real-world farm conditions, from drift control to improved penetration. Each formulation is designed to make existing spray programs more efficient, helping producers boost performance, reduce waste and get consistent results across every acre.

The Hidden Costs of Poor Spray Performance

Every grower knows that spraying isn’t just about getting across acres, it’s about getting every droplet to do its job. But when spray mixes aren’t optimized, a portion of that investment never reaches the plant. Improper mixing can cause uneven droplet formation, leading to drift or evaporation before the spray even lands. Each droplet that misses its target represents wasted chemical, wasted fuel and wasted time.

The math adds up quickly. A few percentage points of lost coverage on a 500-acre field can mean hundreds of dollars in wasted inputs, money that could have gone toward fuel or fertilizer. Drift losses don’t just affect the bottom line; they increase environmental risk and the potential for off-target damage.

Improving efficiency through better spray performance isn’t just good economics, it’s good stewardship. When adjuvants improve spray behavior, farmers make fewer passes, reduce chemical runoff and achieve more consistent yields. In today’s tight-margin environment, sustainability and profitability often go hand in hand.

How Adjuvants Improve Every Application

Adjuvants may only make up a small portion of the tank mix, but they can make a big difference in results. These additives fine-tune how droplets behave from nozzle to leaf, helping farmers get more value from every chemical they apply.

Three main types that matter most on the farm:

-

Surfactants: break surface tension so droplets spread evenly across the leaf.

-

Drift control agents: keep droplets heavier and more uniform, reducing the risk of loss in windy conditions.

-

Spreader-stickers: improve adhesion so sprays stay in place even after a light rain or irrigation.

In practice, these products mean better coverage, stronger leaf penetration and faster uptake. For a farmer, that translates to fewer re-sprays, more consistent control and a stronger return on every spray pass. WC Processors formulates each adjuvant with that purpose in mind, helping farmers get maximum efficiency without unnecessary complexity.

What Makes WC Processors Adjuvants Different

Many adjuvants on the market are designed to meet broad, national standards, but not all of them are built for real Midwest growing conditions. WC Processors takes a more practical approach, developing farm-tested formulations that perform where it matters most: in the field.

Unlike generic products, WC Processors adjuvants are built around the needs of regional crops, local weather patterns and the equipment farmers actually use. The goal isn’t to complicate spray programs, it’s to make them simpler, more predictable and more effective.

Here is how WC Processors compares to typical off-the-shelf options:

|

Feature |

WC Processors Adjuvants |

Generic Products |

|

Formulation |

Custom-blended for Midwest crops and conditions |

Standard, one-size-fits-all mixes |

|

Components |

Naturally derived ingredients insure better up take of chemicals and plant compatibility |

Chemically based formulations that cause chemical resistance and are costly |

|

Service |

Farmer-direct support and bulk delivery |

Distributor-only access |

|

Value |

Affordable and performance-tested |

Higher price, less flexibility |

The result is a reliable lineup of products that combine performance with practicality, helping growers get the most out of every spray pass without adding unnecessary cost or complexity.

Choosing the Right Adjuvant for the Job

Not every spray program is the same, and choosing the right adjuvant can make or break the performance of an application. WC Processors offers a straightforward lineup designed to cover the full range of farm needs, from drift control to improved coverage and sticking power.

-

Drift Control Maxx: Ideal for aerial or windy conditions. Keeps droplets heavier and uniform, minimizing off-target movement and ensuring that every pass stays productive.

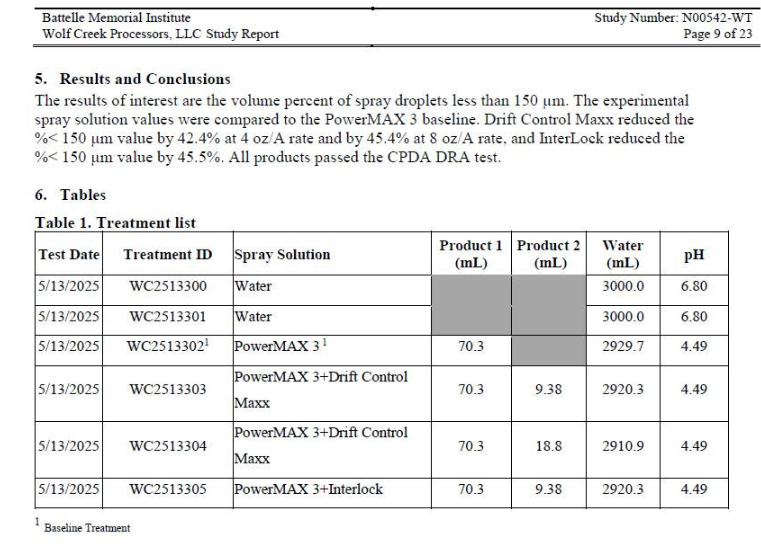

Now verified as a “Drift Reduction Agent,” achieving more than 45% reduction in driftable fines in independent lab testing by Battelle Memorial Institute, surpassing the 30% threshold required for DRA classification.

-

Wolf Oil 90-10: A non-ionic surfactant that delivers excellent spreading and penetration, helping sprays reach deep into plant canopies and improving overall leaf absorption.

-

Wolf Oil 60-40: A high surfactant oil concentrate that provides balanced wetting and sticking for broad-acre applications, helping active ingredients stay in place longer and resist wash-off.

Matching the right adjuvant to the spray mix and crop type can significantly improve efficiency. The right product not only enhances coverage but also reduces the need for reapplications, saving both time and fuel. For growers balancing multiple crops and spraying windows, that kind of reliability keeps operations running smoothly and profitably.

Real-World Results from the Field

Results in the field speak louder than any label. Across the Midwest, growers using WC Processors adjuvants are seeing measurable improvements in efficiency, coverage and cost savings.

A soybean grower in Iowa saw a 45% reduction in driftable fines after switching to Drift Control Maxx. With more uniform droplet formation, his herbicide applications stayed on target, even in breezy conditions. The improved control meant fewer retreatments, saving both time and chemical costs.

On an eastern South Dakota corn operation, the crew integrated Wolf Oil 90-10 into their spray program for better penetration and spread. By improving how the chemical interacted with the leaf surface, they cut overall chemical use by eliminating respray issues while maintaining consistent crop protection. The operator noted that “our fields were clean with neighbors asking what made you different,” a simple but powerful indicator of improved efficiency.

In both examples, the lesson was clear: better adjuvants aren’t about adding expense, they’re about improving performance and protecting profitability in every pass across the field.

Final Takeaway

In modern crop production, efficiency comes down to precision and adjuvants are one of the most effective, affordable tools to get there. A few ounces in the tank can mean better coverage, less drift and more consistent results across acres.

For growers looking to stretch every dollar while improving spray performance, adjuvants are no longer optional, they're essential. They help every application do more work with fewer inputs, supporting both productivity and sustainability goals.

All WC Processors adjuvants have been approved for use with Enlist One and Enlist Duo herbicides and are currently under review for CPDA certification approval.

Learn more about farm-tested adjuvants and practical spray efficiency solutions at WCProcessors.com, where better performance starts with smarter chemistry.